SynchroBloc

The SynchroBloc is the new machine designed to directly connect the Kosme technology for the bottle blow molding with the bottle filling, with no need of air conveyors. The single block for stretch blow moulding and filling carries tangible advantages to the customer:

- The layout simplification thanks to the elimination of conveyors between the blow-moulder and the filler

- Capital and running cost reduction

- Water- and energy-saving

- Reduction of format change-over times and, more generally, of maintenance.

- Need of one only operator

- Transfer stations with short conveying and cooling distances for the bottles

- Filling system which may be optionally connected with different filling valves

- Modular design for the combination of several capper carousels

- Simple line layout thanks to the elimination of transport paths between the blow moulder and the filler

Kosme Blow Moulder cavities KSB R

More time availability for processing thanks to the stops time reduction granted by the new patented sealing system and to the fast deaeration

The simplified system of preform through the machine grants the maximum working reliability.

Systems of production with low energetic consumption in the heating and stretch blow moulding

High working flexibility and repetition precision

Excellent accessibility, utmost simple working and maintenance

Utmost rapidity of the format change-over

Bottles designed by Kosme

Filling technology

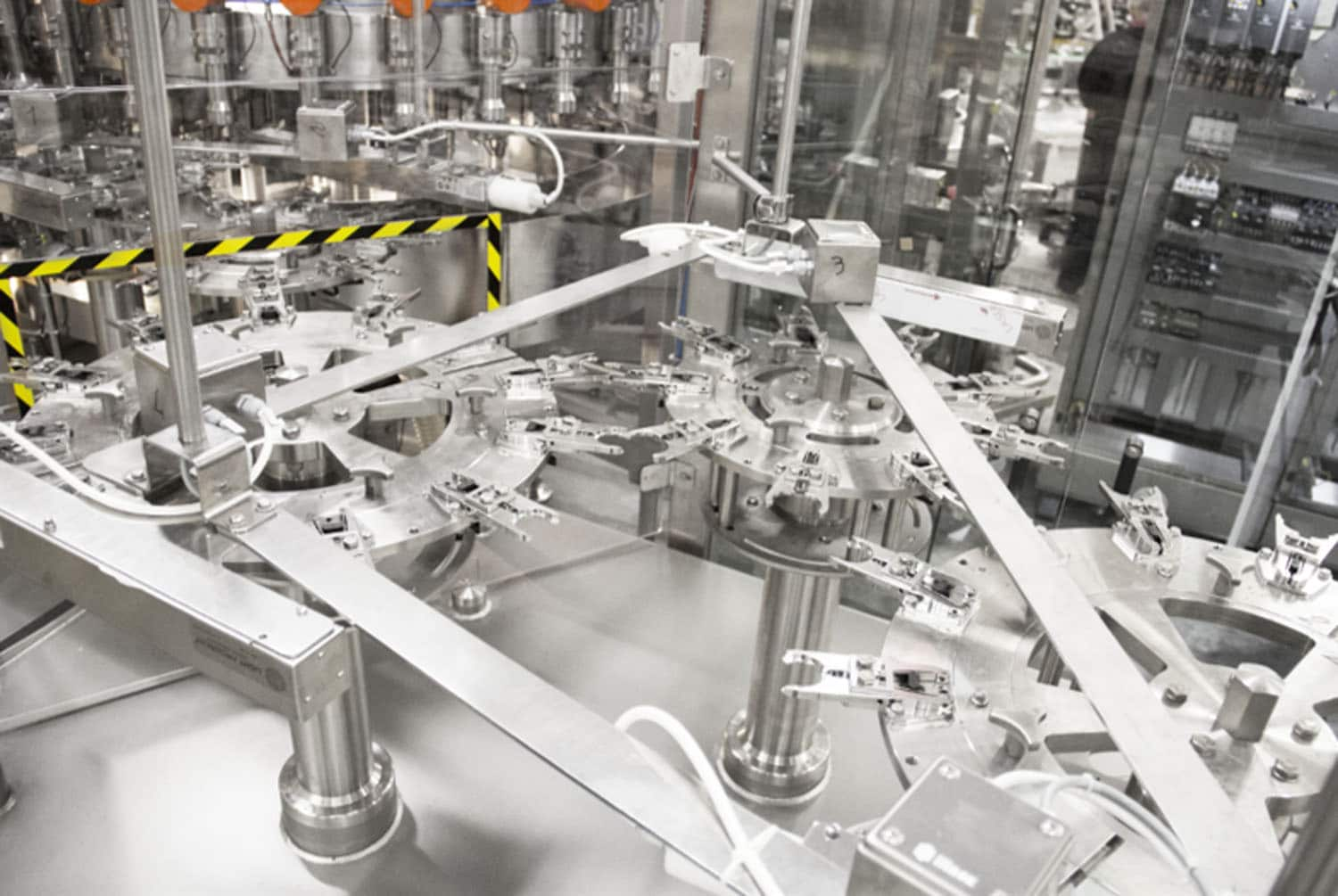

Transfer table

Thanks to the transfer table, remarkably less time involved for transport and cooling-off of the bottles with great advantages concerning less overall space previously covered by the air conveyors

High precision of bottles transfer from the blowing area to the filling area thanks to the Krones grippers